How to reduce the noise from a pool pump?

A sound pressure of more than 90 decibels (dB) is just about average for the noise level emitted by a pool pump and quite common. And that while swimming pools are the very symbol of relaxation and should by no means be a source of unnecessary noise. But no pool without a pump! So what can you do to make the pool pump quieter?

soniflex has put a lot of thought into this issue and developed an easy-to-implement solution: A do-it-yourself design for a noise-reducing enclosure that you can build around the pool pump to make it quieter. Can such a DIY construction really effectively reduce the poolside noise level? Of course, and we'll show you how to do it - step by step!

Our most popular products for this use case

Installation

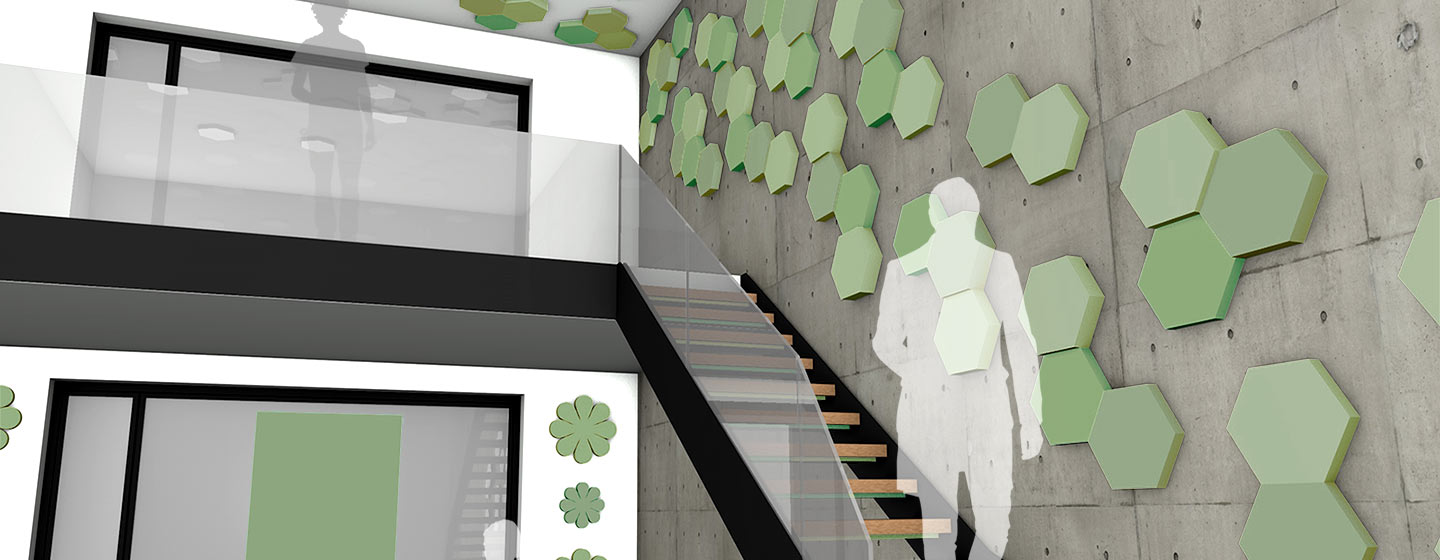

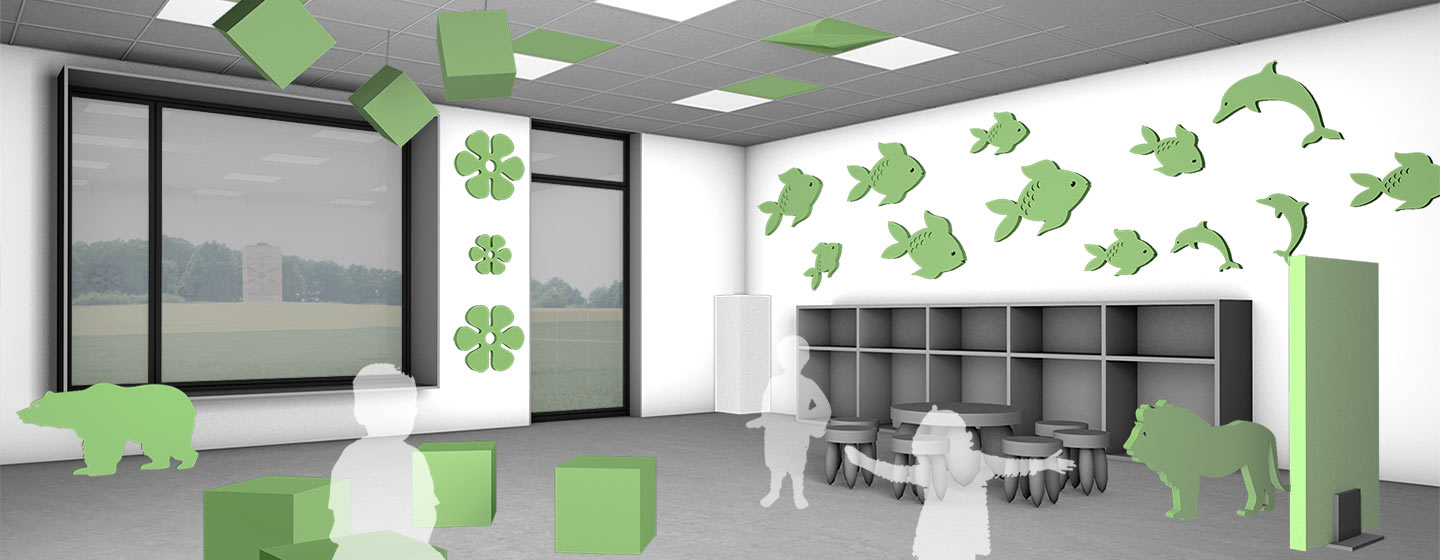

On request, nearly all our products can be delivered with self-adhesive rear faces, enabling easy, clean and time-saving installation – perfect for retrofit applications in rooms that are already in use.

Noise control

Thanks to their open-cell structure, our noise protection materials absorb sound waves and effectively attenuate bothering noise. A satisfactory result can already be achieved by lining 30 to 50 % of the ceiling and wall surfaces.

Fire protection

Many of our noise-control products are classified as flame-retardant according to DIN 4102 or DIN EN 13501. Please contact your local authorities in advance for information about the required fire protection class.

Step 1: Adapt the enclosure design to your needs

We have designed a model enclosure, tested its functionality and came up with a great result: Without our enclosure, the motor of our pool pump generates a sound pressure of 95.4 dB, with our enclosure only 78.5 dB - almost 17 dB lower!

So that you too can benefit from our design idea, we will show you how to implement it yourself in just a few steps. You can copy the design almost 1:1, you only have to adapt it to the dimensions of your pool pump or other noisy device. Very important for planning your project: Remember to decouple the generator acoustically from the ground. To do this, place the generator on an elastic base material, otherwise the sound will be transmitted to the construction in the form structure-borne noise.Click here for our YouTube video on building a DIY enclosure for a pool pump, compressor, etc.

Step 2: Choose suitable building materials

The soundproofing enclosure for a compressor or a pump should have a distance of approx. 30 cm to the device - to allow, among other things, for the heat usually developed by such devices. A 1.5-mm thick steel sheet will provide better insulation values than wood. However, since most users will find it easier to work with wood, we recommend chipboard (thickness: 19 mm or more), which has (almost) the same insulation effect.

Expert advice: The construction must be closed all around, as even small direct openings will considerably weaken the sound insulation effect. Any necessary openings should be designed as sound attenuation channels, i.e. be equipped with an extra element that is lined with acoustic material and redirects the sound waves at least once.Step 3: Choosing the right material for lining the enclosure

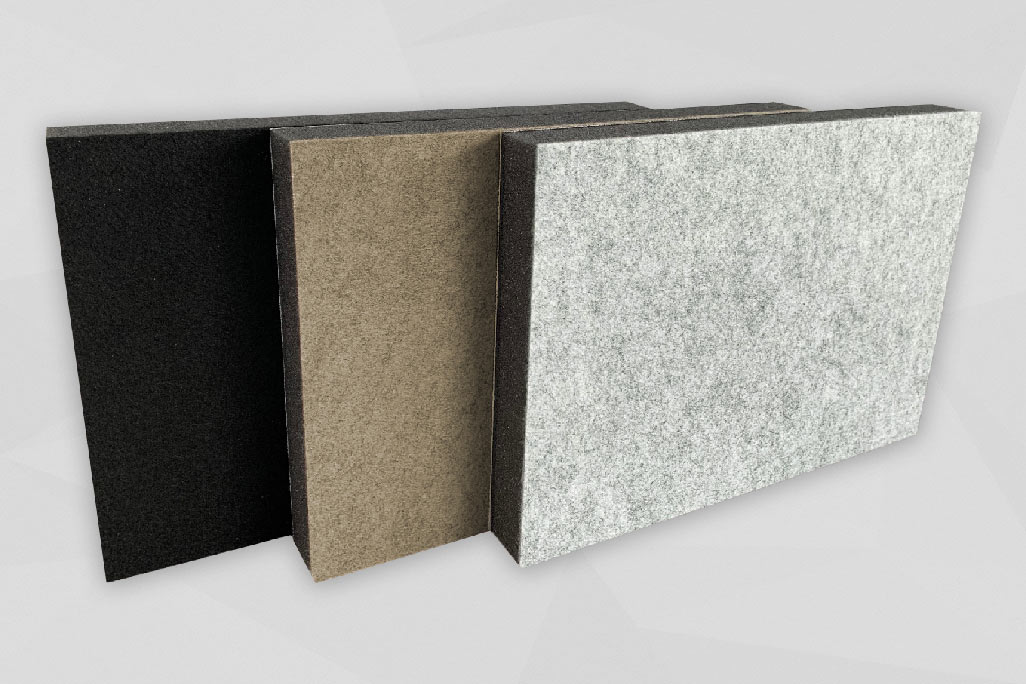

For silencing your pool pump or compressor, the lining of the enclosure plays a particularly important role. You have the choice among several soniflex products, each with its specific advantages, tailored to your needs. For such projects, we recommend our products soni COMPOSITE, soni RESIST and soni WAVE.

soni COMPOSITE consists of a synthetic heavy layer (3kg/m²) and a polyurethane acoustic foam layer, laminated with a non-woven. The heavy layer serves to increase the structure’s mass (higher mass means enhanced sound insulation). The foam serves as sound attenuation layer, i.e. absorbs sound waves. To facilitate the installation of

soni COMPOSITE, we have equipped it with a self-adhesive backing. So the panels can first be glued to the smooth surfaces before being fastened mechanically in addition, to allow for their high weight.

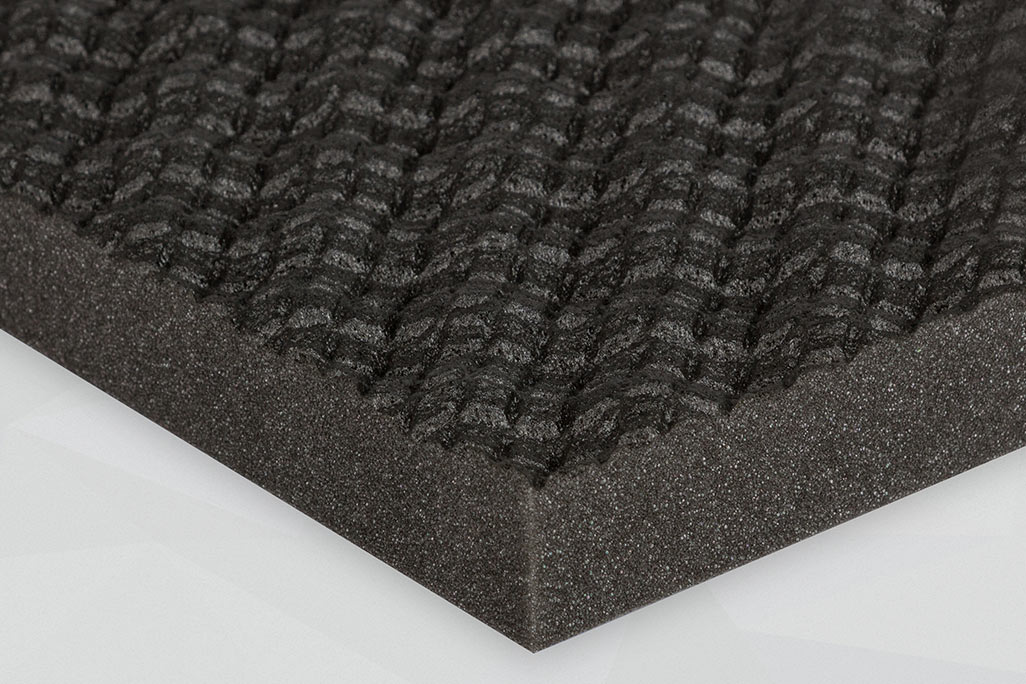

As an especially cost-effective alternative for lining an enclosure we offer soni WAVE, which consists of a PUR foam. The wave-shaped surface achieves excellent sound absorption values in all frequency ranges. Unlike soni COMPOSITE, soni WAVE does not include a heavy layer for an additional sound insulation effect.

If fire safety or resistance to moisture / humidity are to be considered, soni RESIST is an attractive option. soni RESIST consists of a closed-cell polyethylene foam with both sound-insulating and sound-absorbing properties. The material meets the requirements of DIN 4102 and the B1 test, which means that it is classified as flame-retardant. Its closed cell structure makes soni RESIST especially suitable for applications where the material may come into contact with moisture or humidity.

Step 4: Start building

Have you chosen and bought all materials needed? Then you can start building the structure that will make your pool pump quieter. For successful completion of the project you need the following elements: 1x base, 1x top lid, 2x side walls, 4x “halves” for front and rear walls, 2x offset elements to place before the openings.

After cutting the elements to size, drill pilot holes in the side walls and the base to facilitate fastening the other components with screws, as shown in the picture.Once this frame is completed, take exact measurements to determine the dimensions for the insulation material and cut it to size. As our products soni COMPOSITE, soni WAVE and soni RESIST are self-adhesive, you can simply glue the cut-to-size elements to the inside of the enclosure.

After lining the enclosure with the acoustically effective layer, you can install the two offset walls and fit them too with the soundproofing material. We recommend fixing the offset walls to the front and rear wall halves with the help of spacer screws to keep them securely in place.

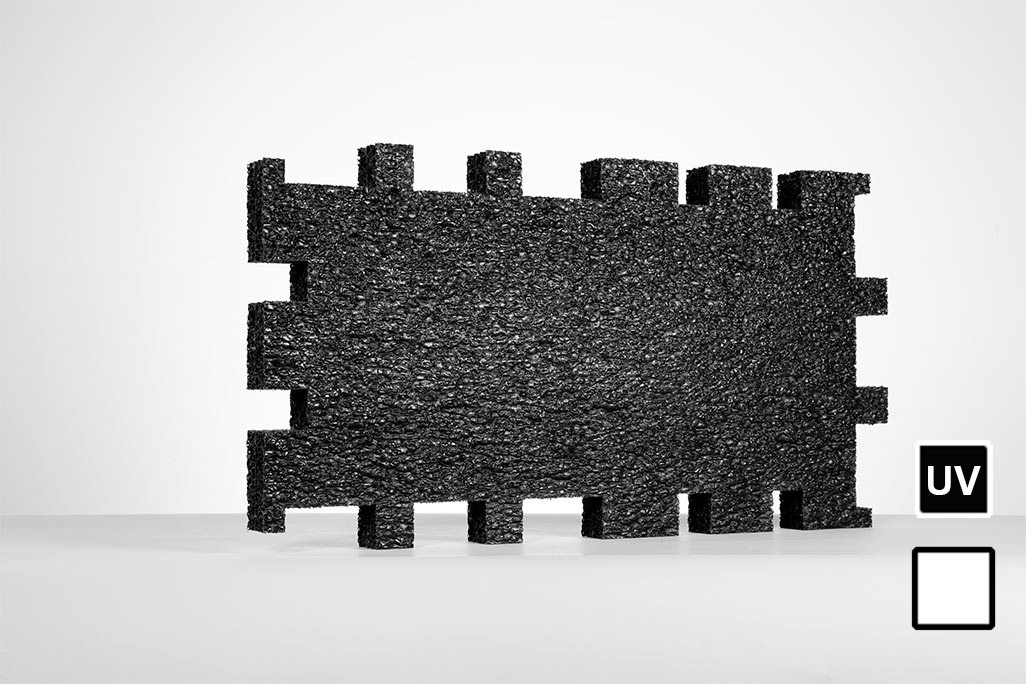

Practical tip: If you do not have the tools or the time to build a wooden enclosure, we suggest our soni RESIST Box UV as a convenient and easy-to-install alternative. The soni RESIST Box is a modular set of acoustic elements from which to assemble a custom-tailored sound insulation box in just a few minutes. The acoustic elements are made of closed-cell polyethylene foam and are available in two different sizes. You can simply plug them together like puzzle pieces to create the soundproofing box.

Thanks to its excellent sound-insulating and sound-absorbing effect, the soni RESIST Box is often used as an enclosure for compressors. But it is also perfect for making a pool pump quieter, even in cases where it is exposed to the weather.

Please note: The extent (as measured in dB) to which the sound level will be reduced in your use case depends on the initial situation (specific application, initial sound level, frequency range of the noise, etc.). Hence it is not possible to predict an exact value.