Sound insulation of an apartment

A family reports:

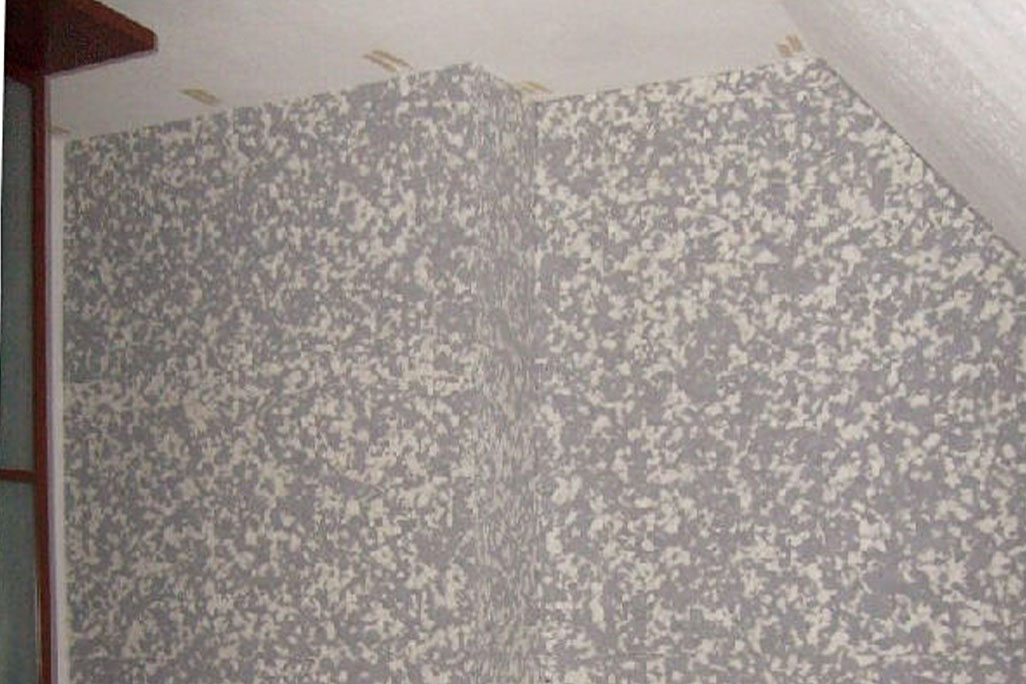

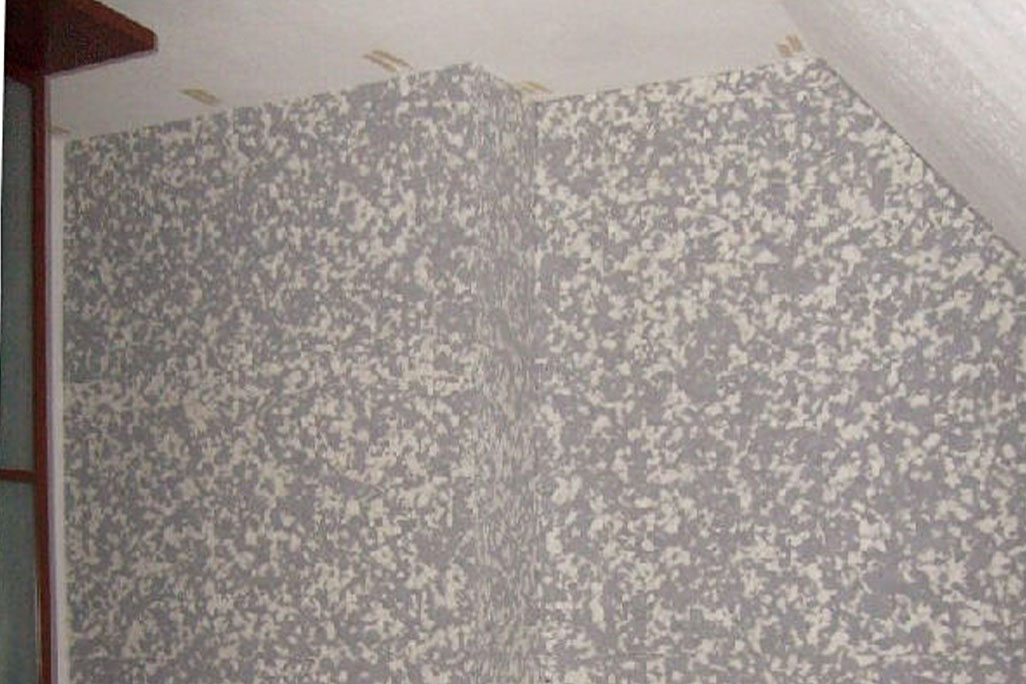

We live in a multiple-family house built in 1920. The individual apartments are separated by ordinary, relatively thin walls that do not block off noises and voices, for instance people talking loudly or children shouting and crying. To remedy this situation, we decided to cover the partition walls with a sound insulation layer as part of a general refurbishment of our house.

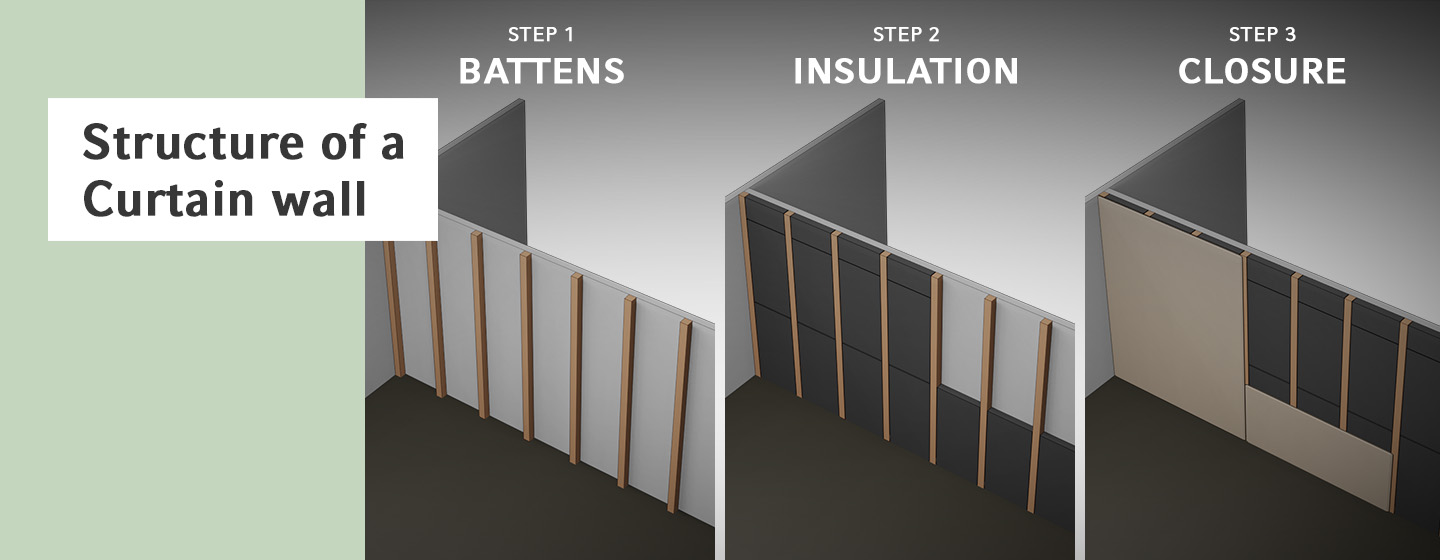

The soniflex team recommended the construction of so-called curtain walling in front of the partition walls to block off the voices and other air-borne noises from the neighboring apartment. For such a curtain wall, a framework of 30 to 50 mm thick wooden slats is fixed to the wall, preferably on elastic spacers to ensure acoustic decoupling. Then soni PROTECT R sound insulation panels are mounted in the spaces between the slats. As a last step, plaster wallboards or particle boards are fixed on the slat framework with screws. An even better sound absorption effect is achieved when the sound protection material, here soni PROTECT R, is not fixed directly on the wall but to the wooden slats (30 mm) before mounting the wallboards.

For optimum overall effectiveness, the wallboards should be decoupled from the side walls, the ceiling and the floor by filling the gaps with acrylic putty.

Handling and cutting the soni PROTECT R sound proofing panels was totally easy and we had no trouble installing the curtain walling. For this we could rely on the detailed and sound advice provided by the very knowledgeable soniflex team. The result was just what we had hoped for: Now the sounds and noises from the neighboring apartment are virtually imperceptible on our side of the wall.

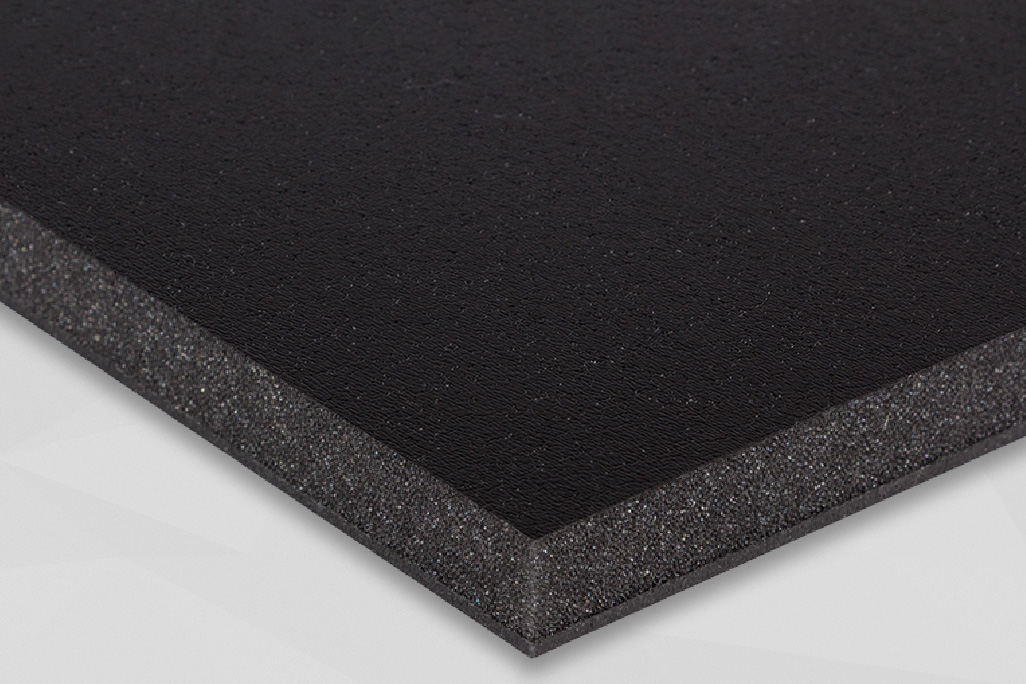

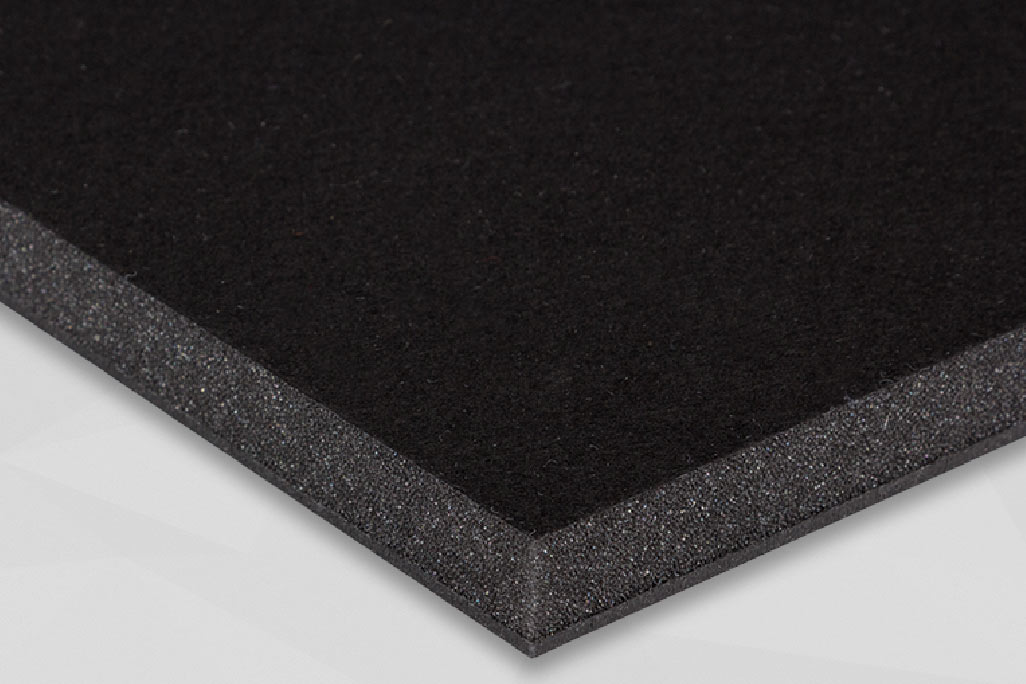

soni PROTECT R is a highly effective sound absorption material and offers higher sound insulation values than melamine foam alone. Used as sound absorber in the hollow space behind a curtain wall, soni PROTECT R achieves a considerable reduction of any resonances that might occur and thus improves the overall sound protection effect.

Note from soniflex06/2024: Our product soni PROTECT R has been replaced by soni 491 STL.

Sound insulation of a ceiling

Our customer reports: Our problem was the high noise level from the apartment on the next-higher floor. To fight this noise, we needed to replace the complete wood ceiling by a new, sound-proofing construction.

In old houses it is often very difficult to define the best solution because of the special construction and building materials used. Our traditionally built ceiling, for instance, was filled with straw and cinder.

We sent soniflex an email describing the problem. They answered promptly with an exact description of what the new ceiling construction should look like and a list of the materials needed.

We ordered soni PROTECT R acoustic panels and cartridges of soniflex special adhesive, which were delivered via DHL.

For the new ceiling construction we used wood laths (4.8 x 5.8 cm) fixed to the walls at both ends and to the ceiling beams at several intermediate points, wherever possible.

The question was how to ensure acoustic decoupling from the existing ceiling. And we had an idea: We simply cut some soni PROTECT R panels to fit the laths' width and inserted them between the new laths and the old ceiling. This was pretty easy to do and the best solution for preventing noise transmission.

Then the soni PROTECT R acoustic panels were glued between the laths on the old wood ceiling, using the special soniflex adhesive. The adhesive could be applied either in individual dots or in a zigzag pattern, as best fit the situation. Then plaster boards were fixed to the laths, the gaps filled with putty and the surface smoothed.

With the 5.8 cm thickness of the laths and the additional soniflex material between laths and old ceiling, there was a hollow space of 0.5 to 0.8 cm left between the soniflex material and the plaster board. According to soniflex, the air in this space acts as an additional insulation layer. We also followed the instructions of soniflex to leave a gap between the plaster boards and the wall and fill it with an acrylic sealing material for acoustic decoupling of the boards and the walls.

With the support of soniflex and of course their soni PROTECT R material, it was possible even for laypeople like us to achieve a very good sound protection result.

Note from soniflex06/2024: Our product soni PROTECT R has been replaced by soni 491 STL.

Sound-proofing a row house

A family from Hamburg (Germany) reports on their experiences with sound-proofing a semi-detached house:

The wall between our half of the house and our neighbors’ half is only about 20 to 25 cm (8 to 10 inches) thick and not sound-proofed. On one side of the wall is our living room, on the other side our neighbors’ bedroom. Already prior to moving into the house we realized that noise passed easily through the thin wall between the two house halves.

The customer consultants at soniflex suggested that we use curtain walling to sound-proof the partition wall.

Based on the in-depth advice provided by soniflex per e-mail, we ordered 10 m² (about 110 square feet) of

soni COMPOSITE noise protection panels and glued these to wall, which we had smoothed out with smoothing compound beforehand. The self-adhesive on the panels’ rear face worked just perfectly! Then we used screws of a length of 6 cm (2.5 inch) to mount a framework of wooden slats over the

sound insulation panels all along the wall. Then we fixed plaster wallboards on this framework, which made it possible to achieve an almost perfectly aligned curtain wall.

We smoothed out the installed wallboards with a suitable compound. The gaps at the outer edges were closed with white acrylic putty from the building supplies store. After a curing time of 24 hours, we applied another coat of smoothing compound to ensure a perfectly level substrate for the coat of paint. We are VERY pleased with the result.

1. This sound insulation measure proved just as effective as we had hoped. Thanks to the curtain walling and the sound absorber panels, noise transmission between the two parts of the house has been reduced to a minimum! Now we can sit and talk – or party – in our living room until late at night without interfering with our neighbors' sleep. With the sound-proofing panels installed, no noise gets through the wall anymore!

2. We are very pleased with the high quality of the sound insulation material, as well as with the soniflex team's in-depth advice, which was exactly tailored to our problem. As we could rely on skilled helpers, implementing the suggested sound-proofing measure was really easy.

Sound insulation of flat

Our customer reports:

The noise from the apartment next door was just too much, so we had to find a noise insulation solution. We live in a maisonette that shares a wall made from limestone bricks with the maisonette next door. The building dates from 1987. Even though limestone is supposed to dampen sound, noise from various sources (radio/TV, telephone and general conversations, walking) in our neighbor’s apartment could be heard loudly through the wall. This noise problem was also perceived by our visitors.

The design of the building, especially the position of the spiral stair leading to the second floor, restricted the overall thickness of the sound-insulation curtain wall to a mere 50 mm. This led to our choice of

32-mm thick soni COMPOSITE inserted between 28-mm wood laths, on which plaster boards (2600 x 600 x 12.5 mm) were fixed with drive screws. On both the wall and the plaster board sides, the faces of the wood slats were covered with sealing tape to

minimize sound transmission.

The sound-insulation panels were very easy to cut to the right shape and glue into the compartments between the laths. As the total thickness of the wood laths plus the sealing tape on both sides was 30 mm, there was no gap between the plaster board and the acoustic foam and the overall thickness was even below the maximum thickness of 50 mm.

This measure now largely eliminates any normal noises such as walking or radio/TV and also dampens the peak noises, such as a very shrill voice, to a tolerable level. 52-mm panels would probably have led to even better results, but in any case our apartment is so much quieter now than before!

Sound insulation of a bedroom wall against noise from the neighboring apartment.

A client tells us:

In my bedroom, I was often bothered by the noise from my neighbors’ living room, for example the sound of voices, the television, music or laughter. As I live in a rental apartment and my bedroom is quite small, the construction of curtain wall for sound proofing the partition wall as recommended by soniflex seemed too expensive a measure. The curtain walling would also have taken up too much of the limited space. This is why I decided in favor of the simpler alternative of fixing

soni COMPOSITE 52-mm sound protection panels directly to the wall surface. As a large wardrobe was to be put right in front of the wall in question, covering it almost in its entirety, fixing the sound protection panels with adhesive was perfectly sufficient and I didn’t even need to fix the panels mechanically or cover them with plaster wallboards, as recommended by soniflex for such applications in general. The wardrobe not only ensures that the sound protection panels will not come loose, but also provides additional sound insulation.

In combination with the wardrobe, the

soni COMPOSITE sound protection panels fixed directly on the wall proved to be the right solution for the protection of my bedroom against the noises from the neighboring apartment, which are virtually imperceptible now. I am absolutely satisfied with the result. And, what is more, it was really easy to install the sound protection panels.