Enhance your production hall | workshop | utility room with our sound absorbers and benefit from:

- a significantly shorter sound reverberation time

- effective insulation of noise-emitting machines and appliances

- a reduced noise level

- a working environment that promotes concentration and hence safety

- more satisfaction and thus higher motivation of your employees

- a healthier and less stressful work environment

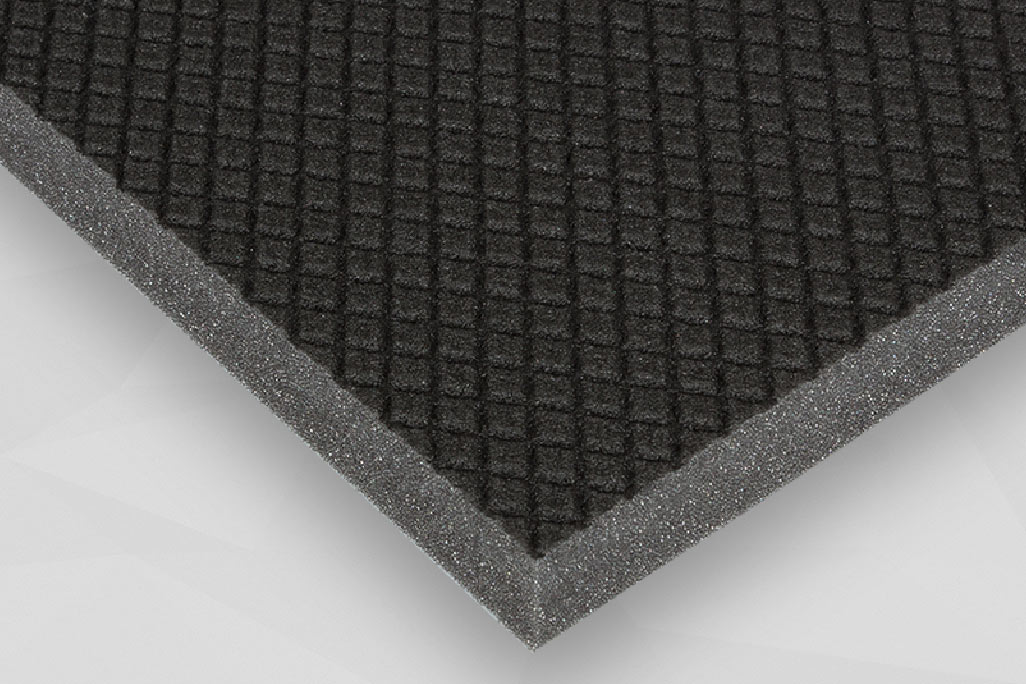

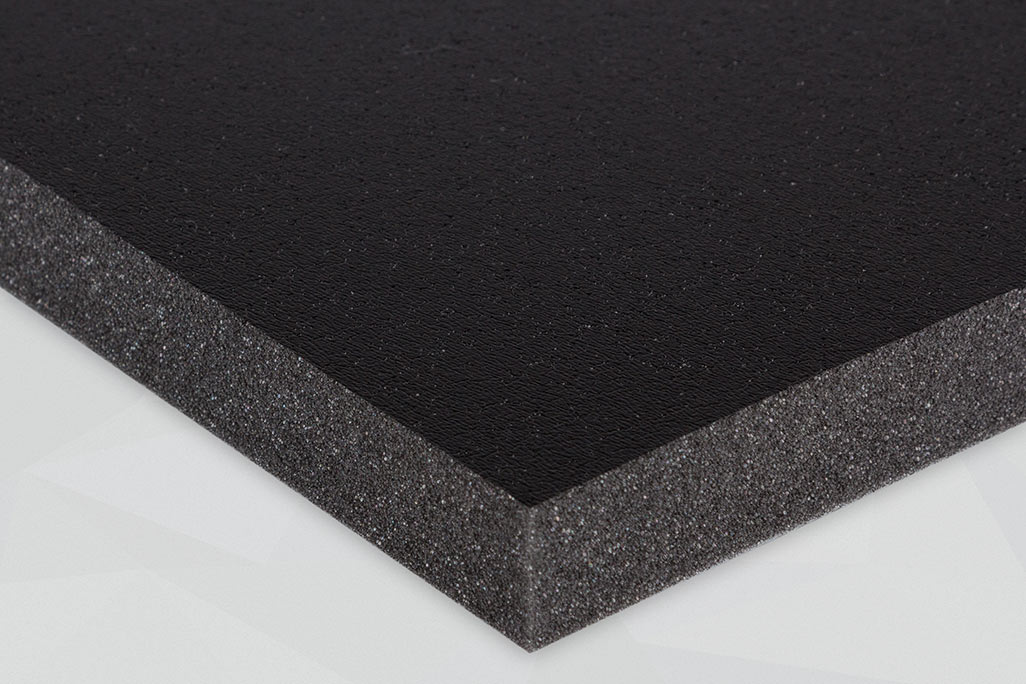

Content: 0.5 m² (€21.80* / 1 m²)

Content: 0.5 m² (€27.80* / 1 m²)

Content: 0.5 m² (€39.80* / 1 m²)

Content: 0.5 m² (€37.80* / 1 m²)

Content: 0.5 m² (€65.80* / 1 m²)

Content: 0.5 m² (€31.80* / 1 m²)

Content: 0.5 m² (€27.80* / 1 m²)

Content: 0.5 m² (€29.80* / 1 m²)

Description

Noise control in productions halls | workshops | utility room

Noise is increasingly identified as one of the strongest stress factors at the workplace. Especially in large production halls with numerous loud machines, the noise level can be unbearably high. This not only creates a counter-productive working environment, but also can have a range of negative effects on health. Permanent noise pollution makes concentrated work more difficult and also increases the risk of accidents. Workplace guidelines and the applicable noise protection regulations therefore require that the noise level at workplaces be reduced as much as possible.

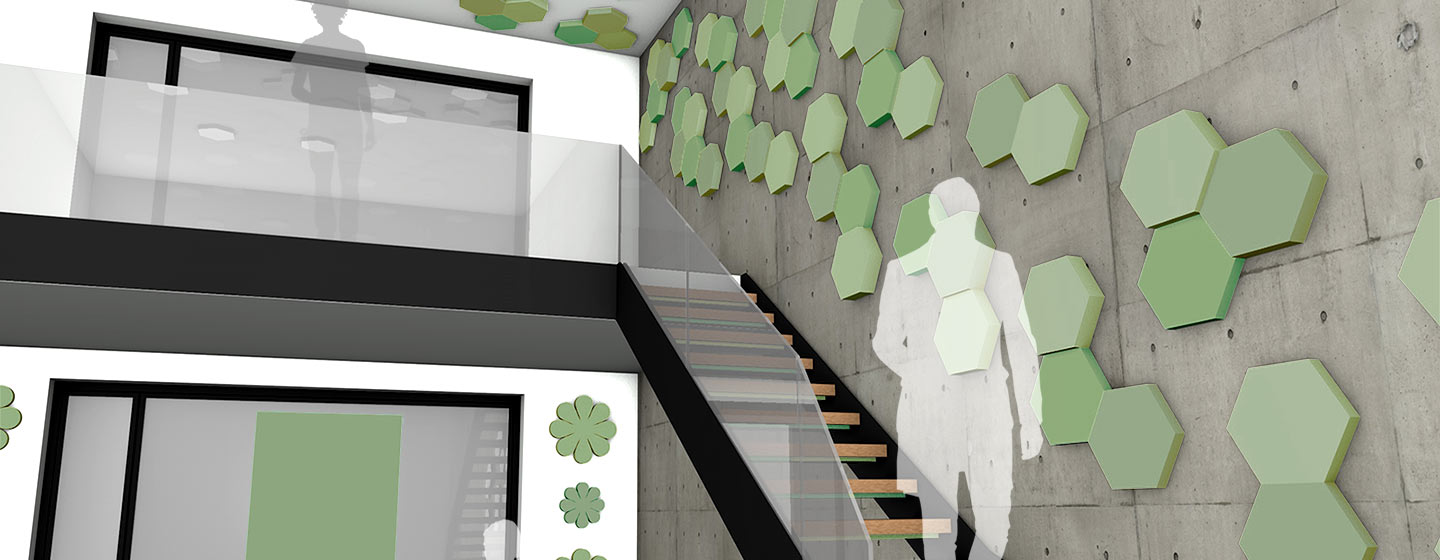

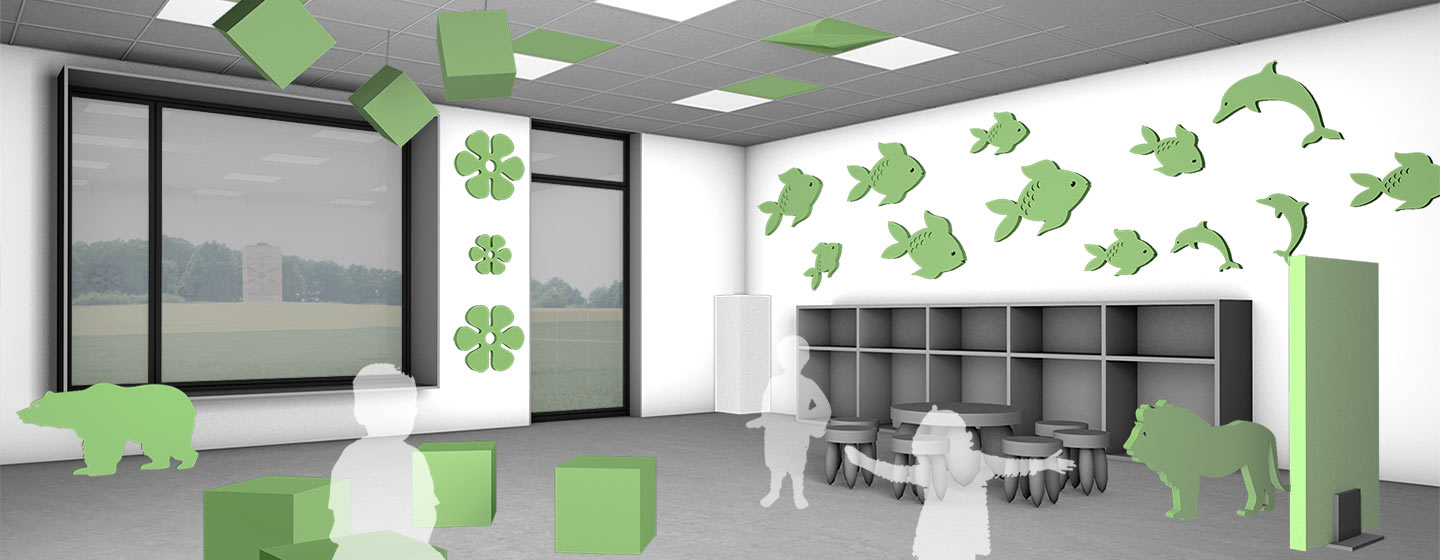

Our special acoustic products for production halls and workshops promote a pleasant, motivating and safe working atmosphere. There are multiple applications and uses. For instance, areas where noisy machines are located can be “fenced off” acoustically. Or noise control products can be installed on ceilings and walls to reduce the level of sound reflection. This shortens the reverberation time and thus reduces the overall noise volume to a tolerable level.

Testimonials

Noise reduction in a work space

Sound deadening of a test bench

Noise insulation of a machine housing

Noise reduction in a garage used as work space

Noise reduction in a basement work space