Equip your machine | compressor with our sound absorbers and benefit from:

- a perceptible reduction of the noise level

- an acoustically effective casing for your noisy machine

- an ideal sound-insulating compressor wrap

- reduced solid-born sound transmission

- reliable protection against the infiltration of oil, dust, etc.

- a reduction of the sound transmission to adjacent rooms

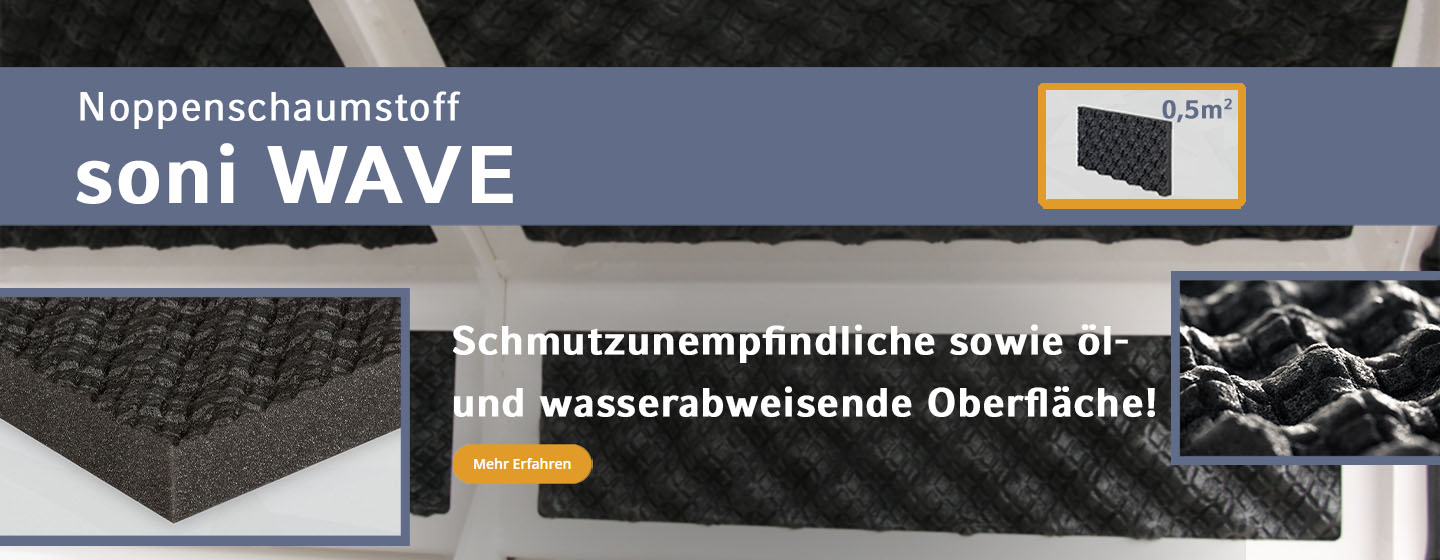

Content: 0.5 m² (€45.80* / 1 m²)

Content: 0.5 m² (€21.80* / 1 m²)

Content: 0.5 m² (€27.80* / 1 m²)

Content: 0.5 m² (€39.80* / 1 m²)

Content: 0.5 m² (€65.80* / 1 m²)

Content: 0.5 m² (€31.80* / 1 m²)

Content: 0.5 m² (€27.80* / 1 m²)

Content: 0.5 m² (€29.80* / 1 m²)

Description

Sound insulation for machines | technical equipment | compressors

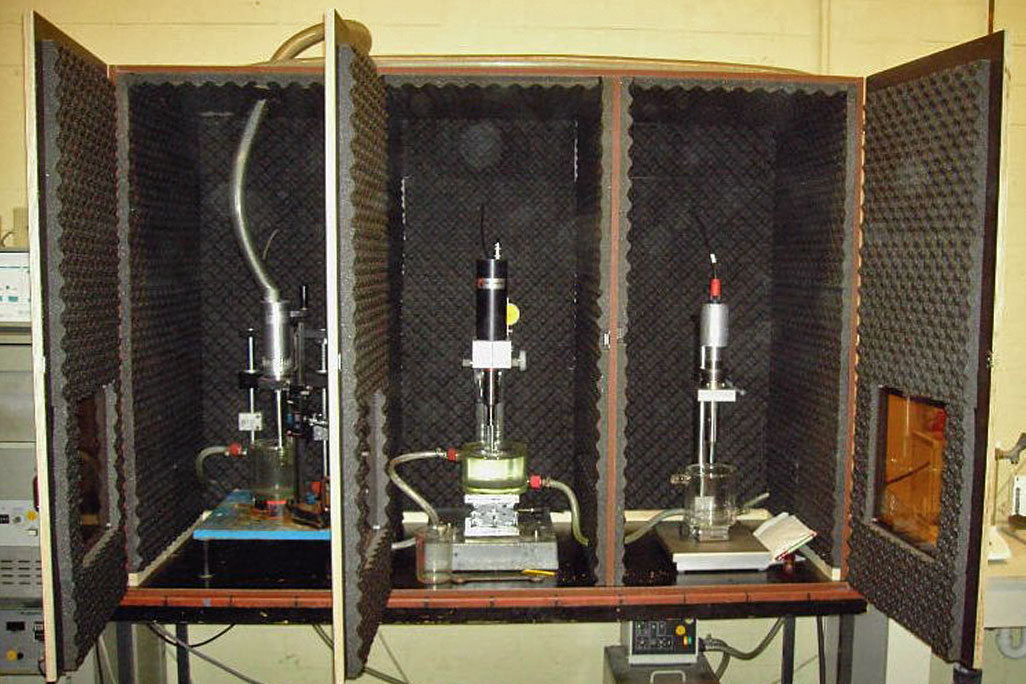

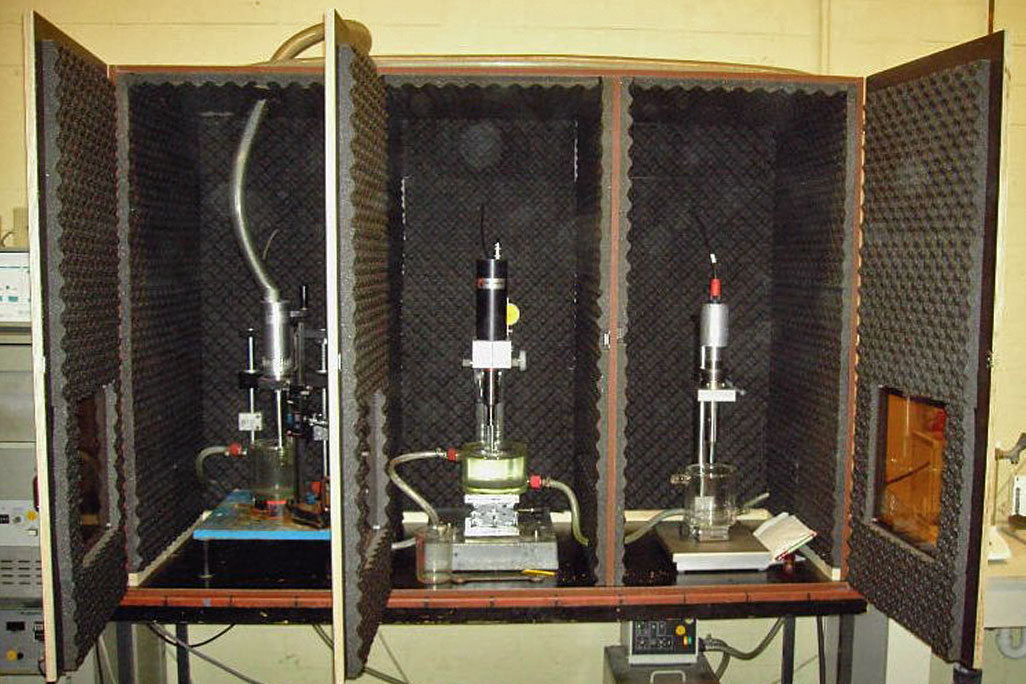

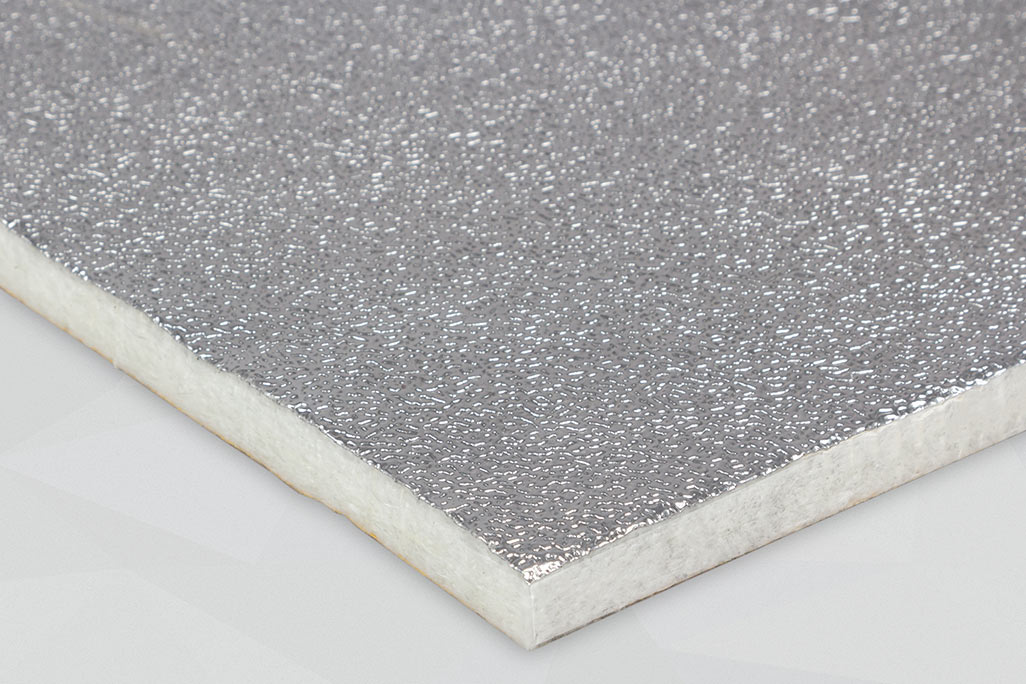

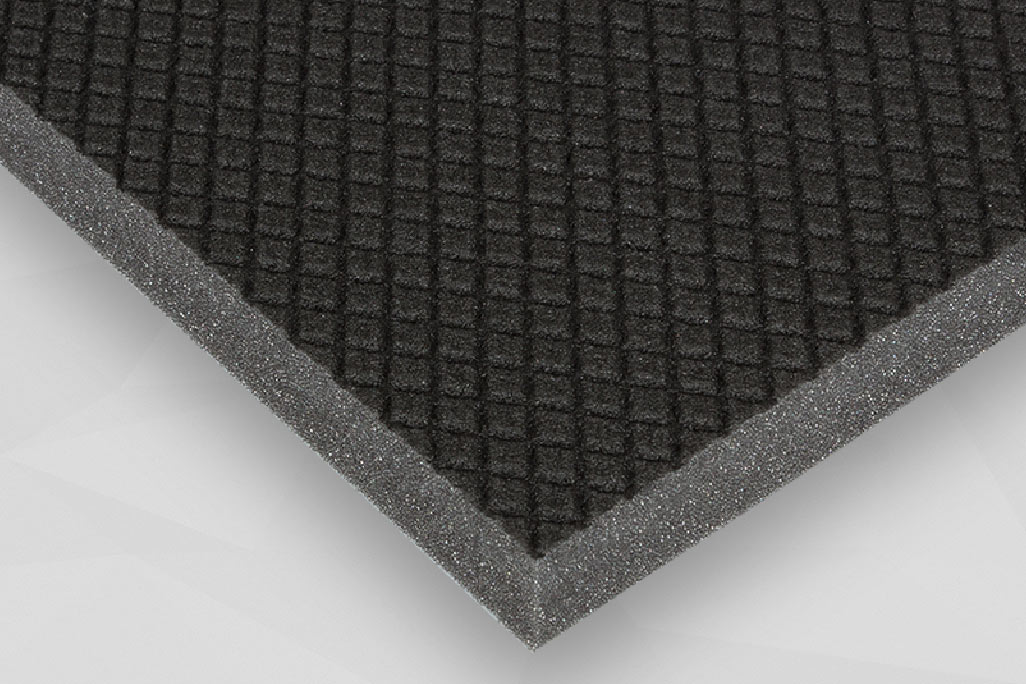

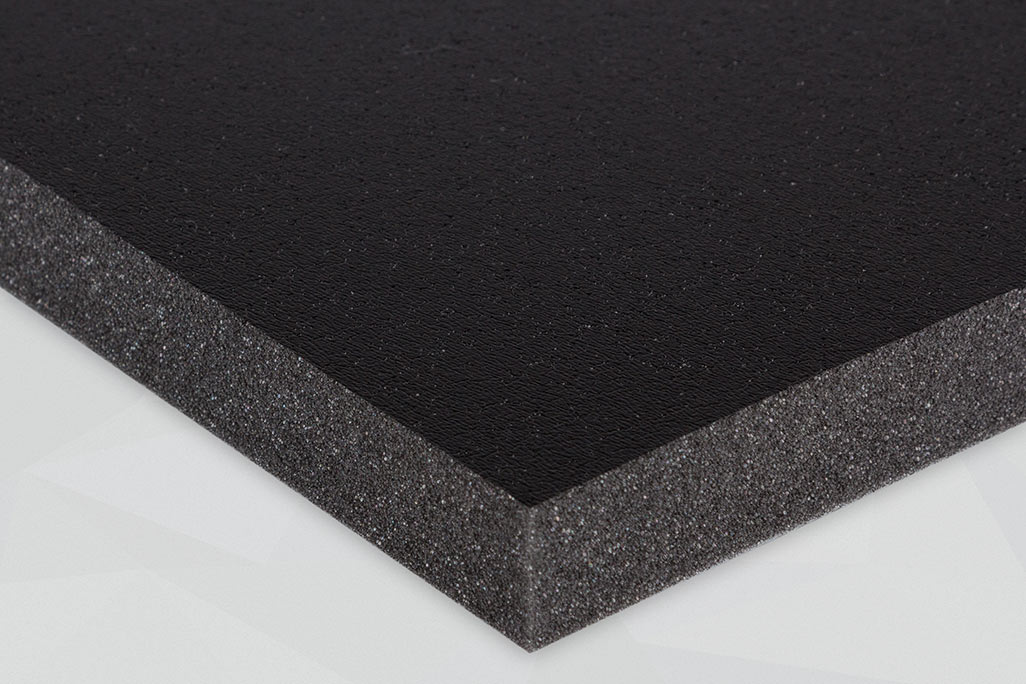

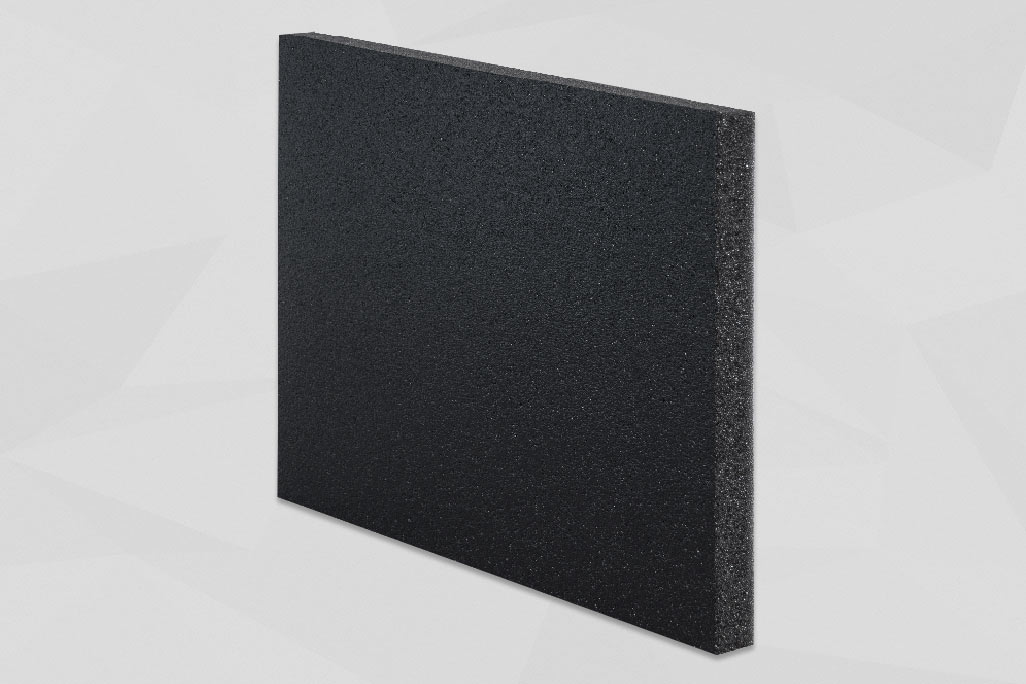

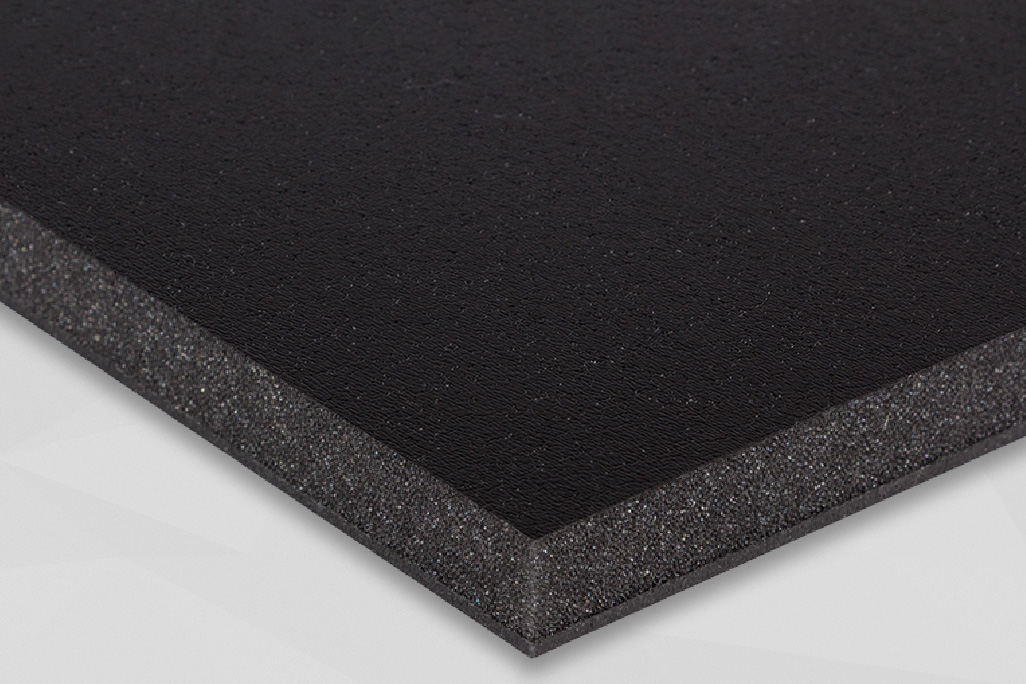

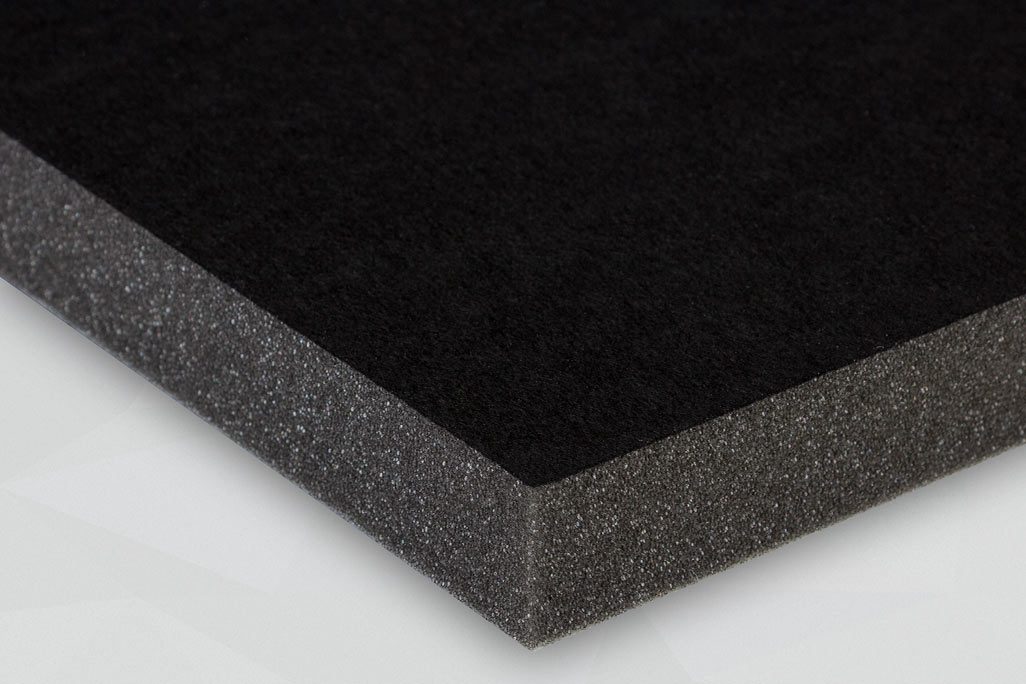

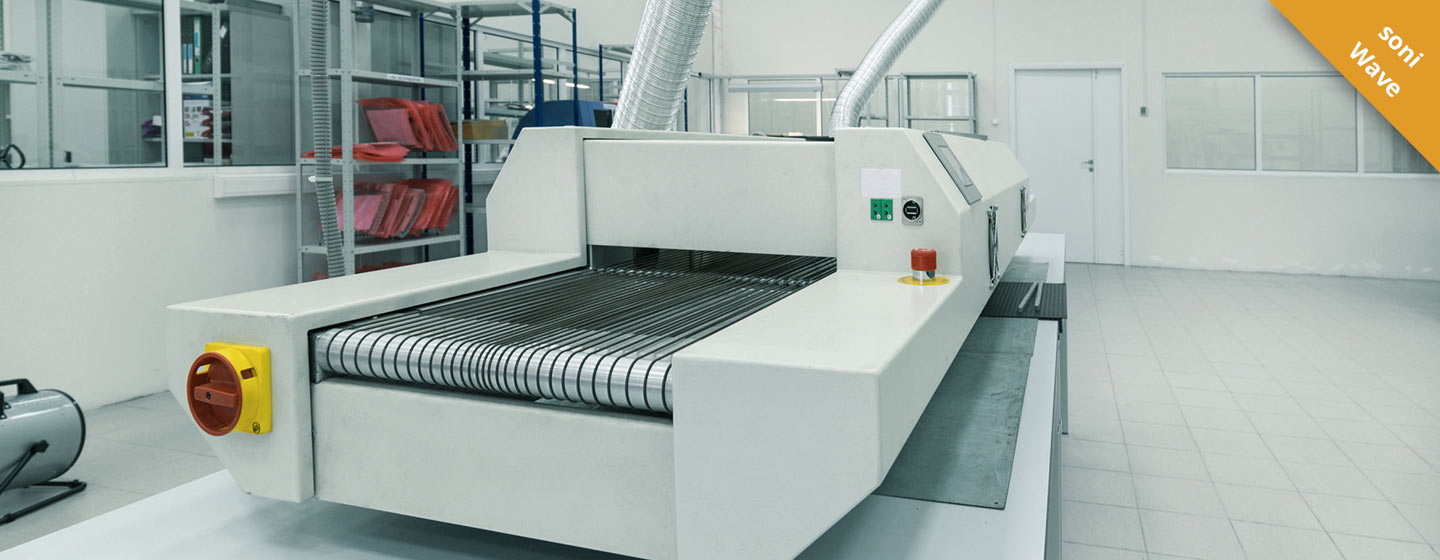

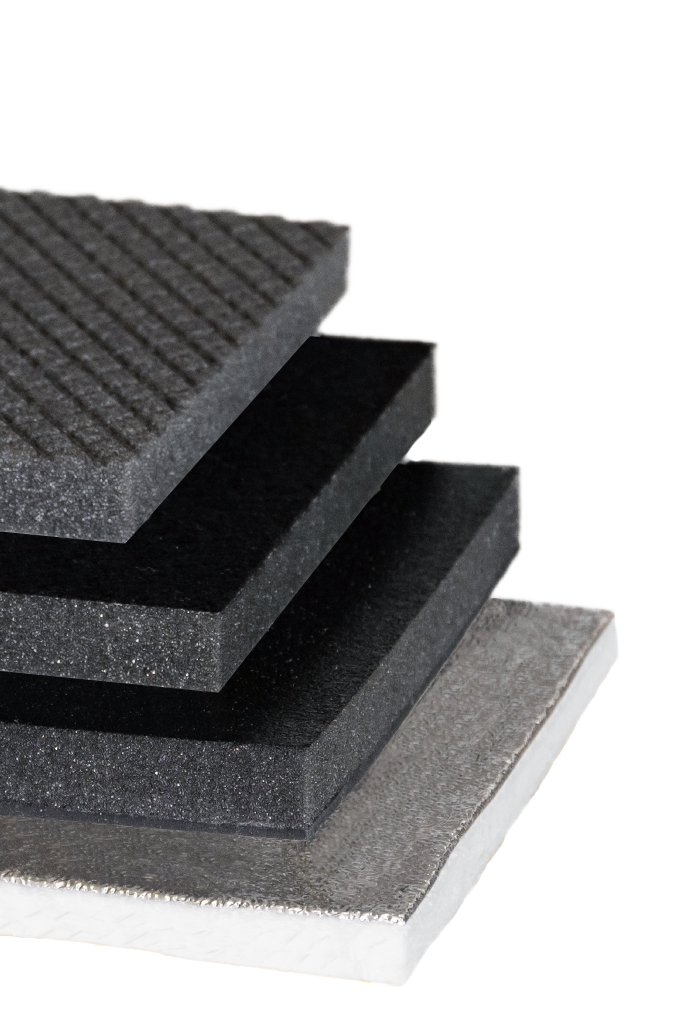

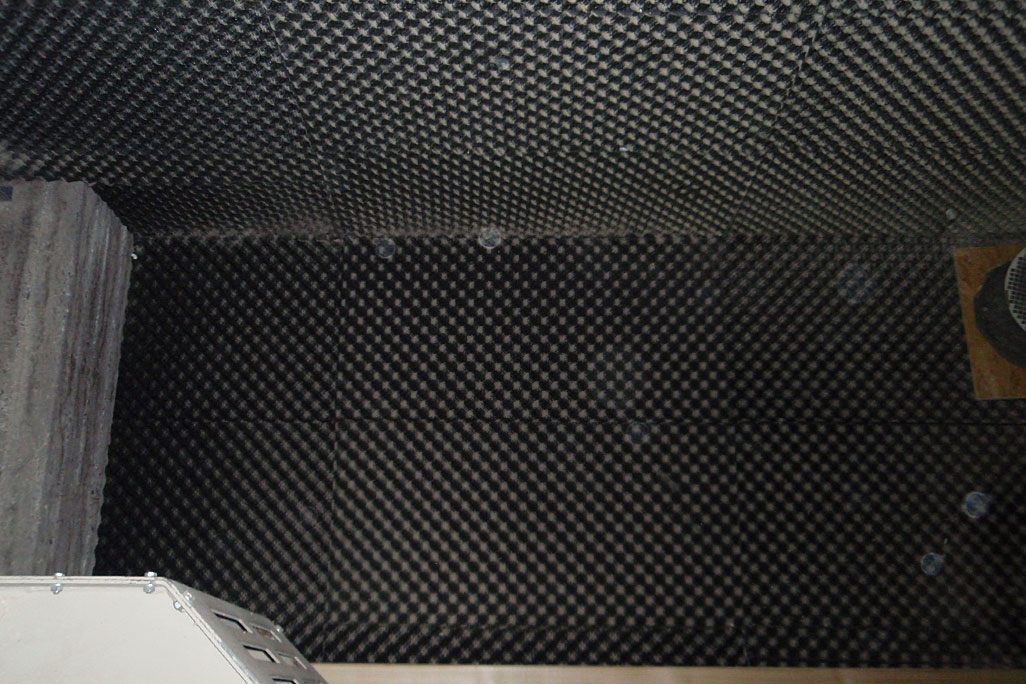

As a rule, any machine, whether large or small, will generate noise. The resulting noise level can be very unpleasant. This is why we recommend enclosing the machine or other equipment with a noise-reducing casing - ideally at a distance of about 30 cm from the actual noise source. The enclosure (made of wood, plastic or sheet metal) should be lined on the inside with sound-insulating material. Perfect for this use are our products soni RESIST, soni COMPOSITE and soni WAVE.

If the machine is located outside, our soni RESIST is the material of choice. It has both sound-absorbing and sound-insulating properties and hence an especially high overall soundproofing effect. Furthermore, soni RESIST is weather-resistant. If, in addition, the sound-absorbing material will be exposed to sunlight, we recommend our soni RESIST UV. With its unique UV stability, it is specially designed for outdoor use. For those particularly noisy compressors, the ideal choice is our soni SB 700, a highly sound-absorbing polyester fleece combined with a heavy layer. This optimum combination insulates and dampens in equal measure and thus provides excellent noise protection.

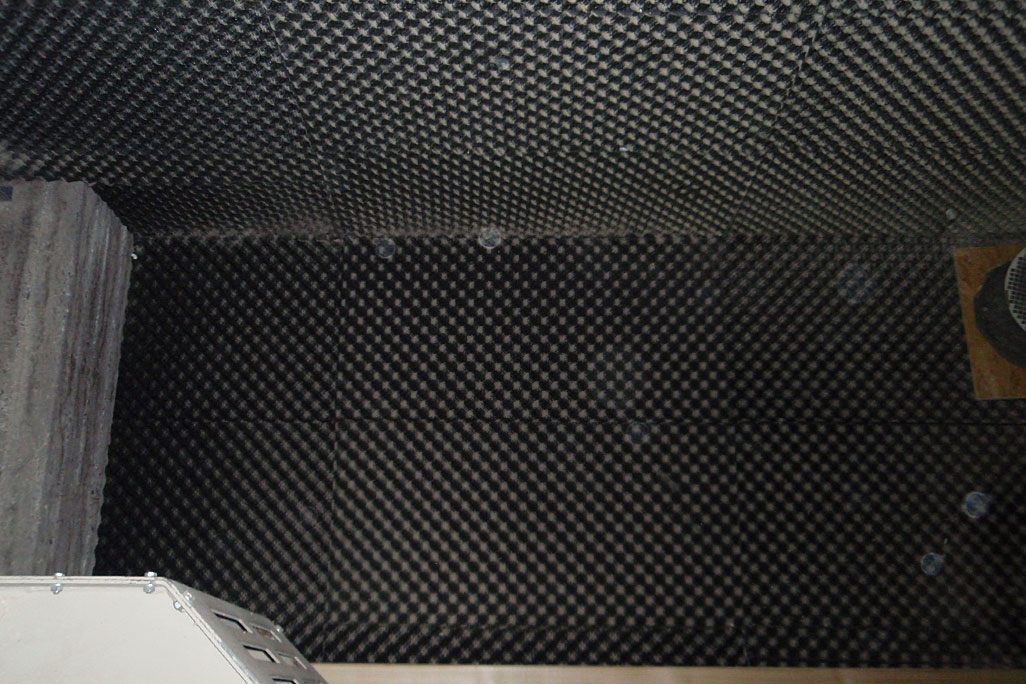

As a further measure, the utility room or workshop containing the compressor, ventilation/air conditioning equipment or a noisy machine can be insulated using sound-absorbing materials. This prevents any annoying noise from being transmitted to neighboring rooms or rooms above. Contact us to find out more.

Testimonials

Chiller noise control

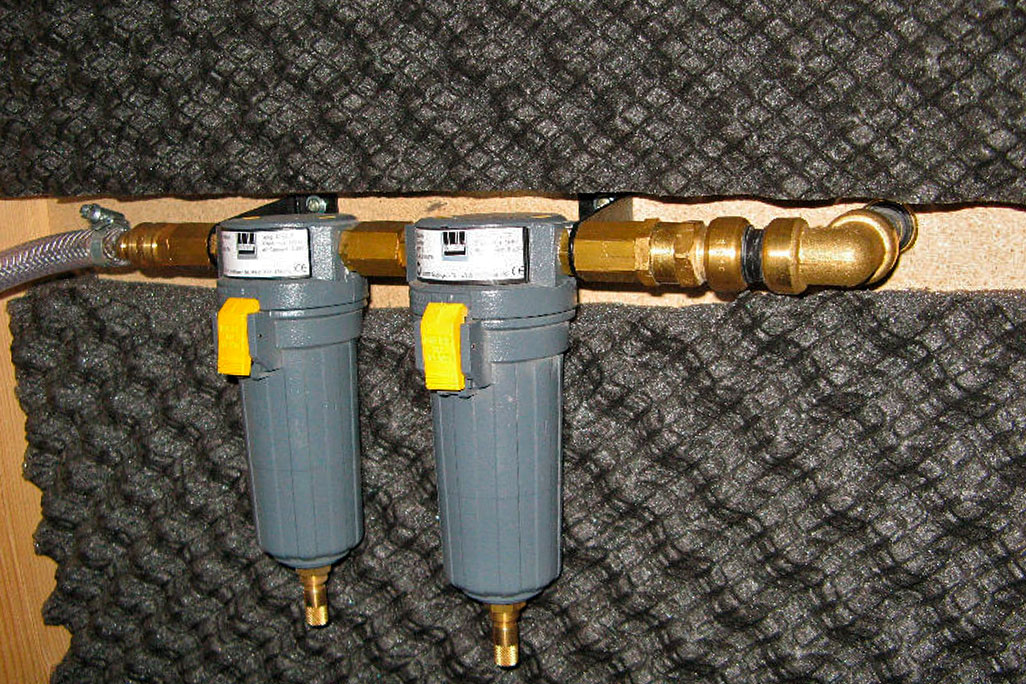

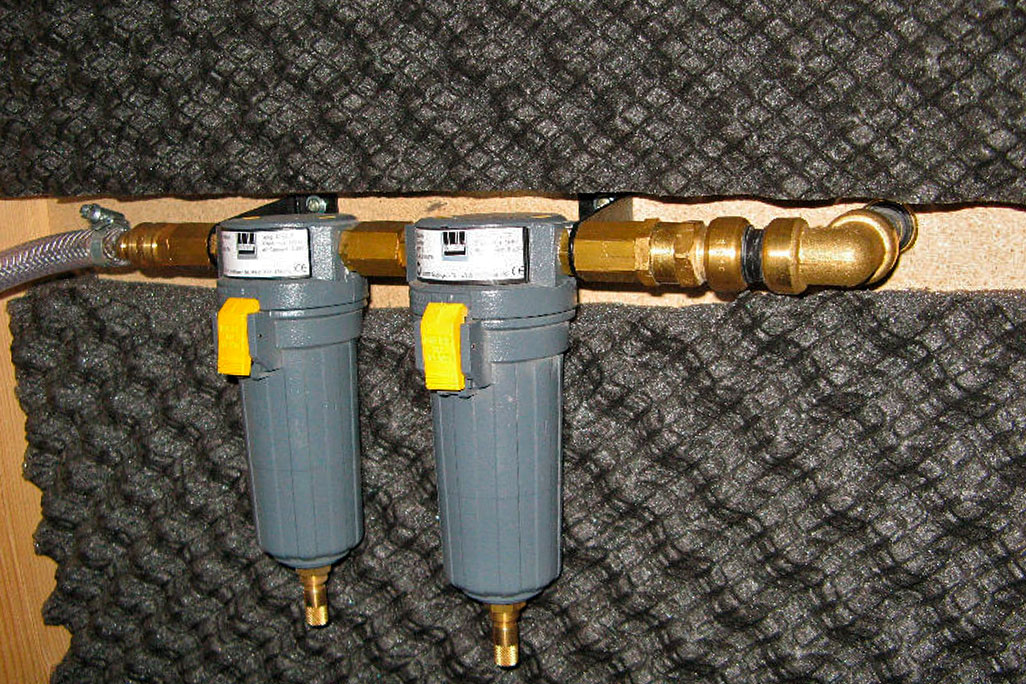

Sound insulation of an air compressor

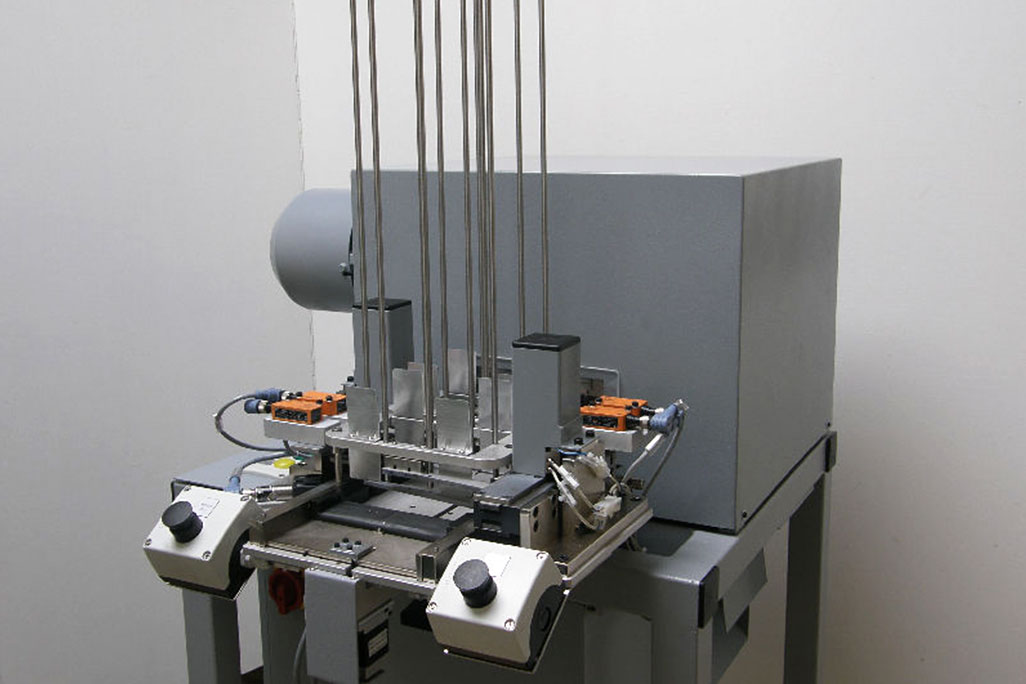

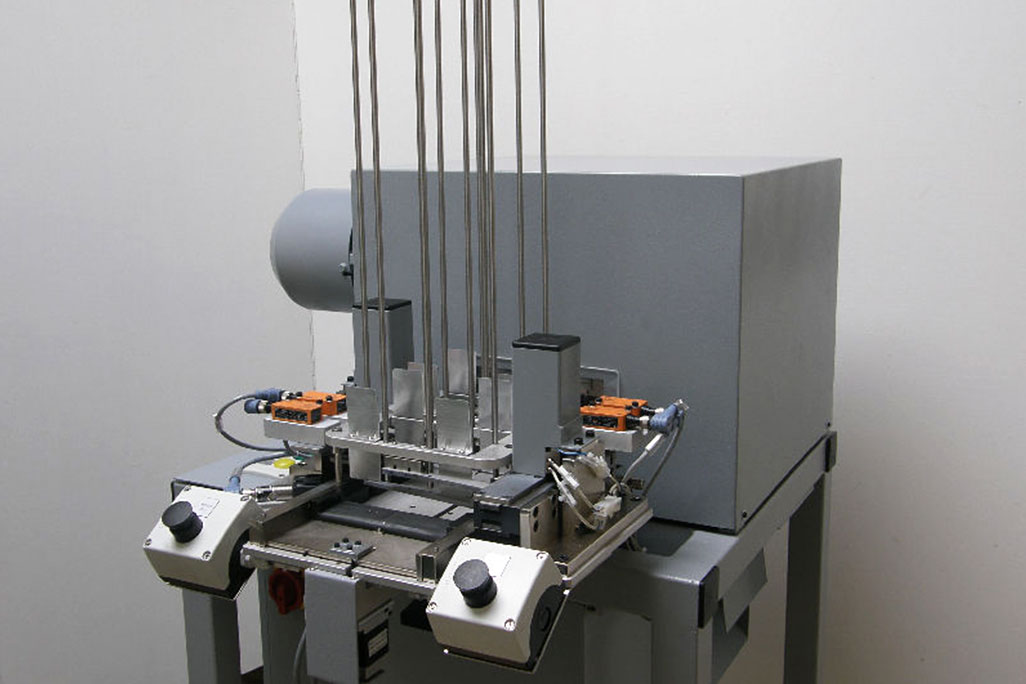

Sound insulation of a machine

Noise reduction in a basement boiler room

Sound insulation of a swimming pool filter pump in a plant room